Glass roof of Moscow Main department store

Moscow, 1890 - 1893

Developer and manufacturer: O.E. Krell

St.-Petersburg metal factory

Moscow, 1890 - 1893

Developer and manufacturer: O.E. Krell

St.-Petersburg metal factory

MARCH - Technology module. ВА2 2019/20.

Daniil Orekhov, Rodion Istoksky, Ilya Filippov, Anna Titova, Polina Solovieva

Daniil Orekhov, Rodion Istoksky, Ilya Filippov, Anna Titova, Polina Solovieva

The glass roof structures above the passages of the Main department store (GUM) are unique in that during their design and construction, for the first time in Russian practice, systems of arches with diagonal ties, developed in the late 1880s - early 1890s by the director of the St.-Petersburg Metal Works Otto Egorovich Krell [1] were used. This type of arched structure was not previously used in European practice nor before neither after that period. It can rightfully be considered an invention of the Russian engineering school at the end of the XIX century.

HISTORICAL CONTEXT

According to the results of the tender, a new building of the Upper Trade Rows was constructed in 1889-1893 on the Red Square on the project of Russian reknown architect A.N.Pomerantsev. The glass coverings of the passages were shown schematically in the architectural project and had to be finalized and produced within the framework of a tender assignment by one of the metalwork manufacturers in Russia. Of the six bidders, the St. Petersburg Metal Works won the tender, offering the most reasonable cost estimate, but also its own unique design solution developed in the plant's technical bureau. Before construction began, a prototype was successfully produced and tested at the plant, and in 1891 a privilege (patent) was applied for a "new system of fastening metal arches", granted in 1897.

According to the results of the tender, a new building of the Upper Trade Rows was constructed in 1889-1893 on the Red Square on the project of Russian reknown architect A.N.Pomerantsev. The glass coverings of the passages were shown schematically in the architectural project and had to be finalized and produced within the framework of a tender assignment by one of the metalwork manufacturers in Russia. Of the six bidders, the St. Petersburg Metal Works won the tender, offering the most reasonable cost estimate, but also its own unique design solution developed in the plant's technical bureau. Before construction began, a prototype was successfully produced and tested at the plant, and in 1891 a privilege (patent) was applied for a "new system of fastening metal arches", granted in 1897.

Construction of the Upper Trade Rows in Moscow. E. Simonov's photo studio. 1890s.

STRUCTURE DESCRIPTION

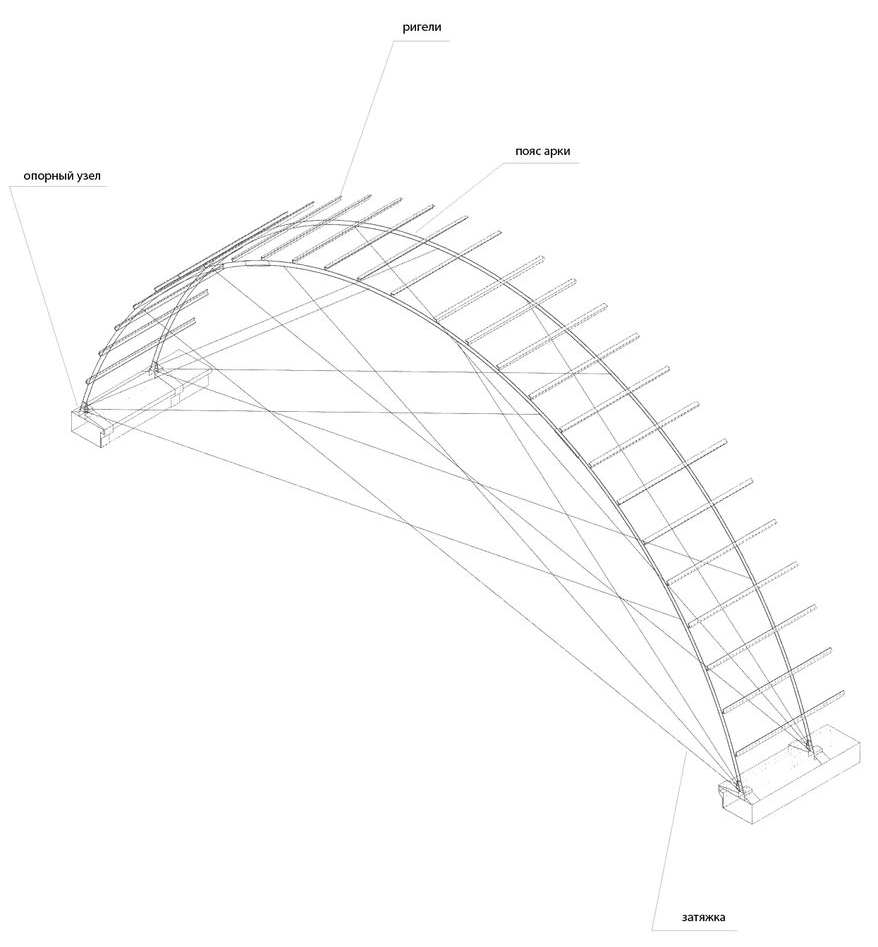

The load-bearing structure of the glass roof is composed of a row of circular arches installed with a spacing of 1.5 in the longitudinal direction on a brick wall. The width of the spans three passage lanes slightly differs and is 14.760 m, 12.236 m, and 15.274 m respectively.

The arches are made of a single steel angle profiles (77 x 55 x 8 mm) bent to the required radius. There are 26 purlins installed on the arches with a spacing of 740 mm for the mounting of the glass panes. Each purlin consists of two angle profiles (40 x 40 x 4 mm), connected by a bolt. The glazing elements are bolted to the purlins and the purlins themselves are bolted to the arch. The arches are semi-rigid and rest on a cast-iron anchor profile.

In order to have an elegant lightweight structure under the Moscow climate conditions with high snow loads, diagonal ties - strings - were used to prevent arches from buckling. They provide stability of the arch, but do not disturb the light passing to the area of passages and are practically invisible from below, being only 1 cm in diameter. Three pairs of diagonal strings radiate out of two opposite supports, fastening to the opposite side of the arch at an equal distance from each other.

The load-bearing structure of the glass roof is composed of a row of circular arches installed with a spacing of 1.5 in the longitudinal direction on a brick wall. The width of the spans three passage lanes slightly differs and is 14.760 m, 12.236 m, and 15.274 m respectively.

The arches are made of a single steel angle profiles (77 x 55 x 8 mm) bent to the required radius. There are 26 purlins installed on the arches with a spacing of 740 mm for the mounting of the glass panes. Each purlin consists of two angle profiles (40 x 40 x 4 mm), connected by a bolt. The glazing elements are bolted to the purlins and the purlins themselves are bolted to the arch. The arches are semi-rigid and rest on a cast-iron anchor profile.

In order to have an elegant lightweight structure under the Moscow climate conditions with high snow loads, diagonal ties - strings - were used to prevent arches from buckling. They provide stability of the arch, but do not disturb the light passing to the area of passages and are practically invisible from below, being only 1 cm in diameter. Three pairs of diagonal strings radiate out of two opposite supports, fastening to the opposite side of the arch at an equal distance from each other.

Isometric view of the structure of the arched glased structure of the passages

STRUCTURAL PRINCIPLE

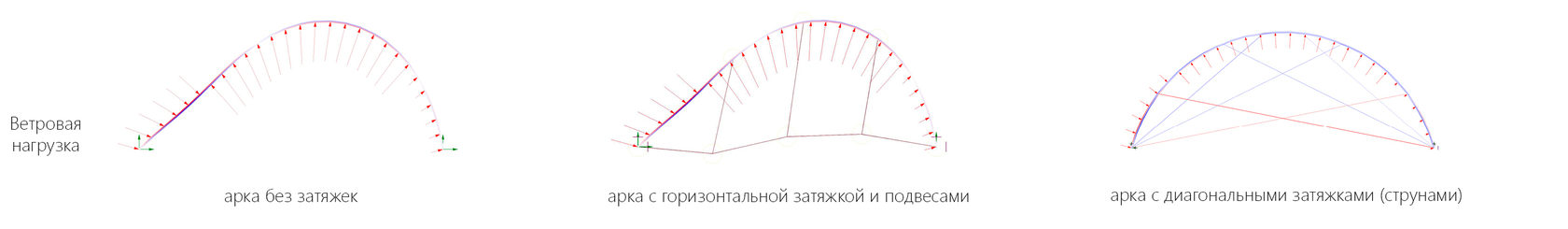

The circular arch transfers loads to the supports, which can be divided into vertical and horizontal components. The latter is called a thrust, which is usually transmitted to the foundations through buttresses or massive wall structures. The spacer can be reduced by decreasing the radius of the arc and increasing the cross-section of the arch, however, this option reduces the light transmission of the structure and is more material-intensive.

The spacer can also be extinguished by installing a horizontal tightening, which greatly facilitates the construction

The circular arch transfers loads to the supports, which can be divided into vertical and horizontal components. The latter is called a thrust, which is usually transmitted to the foundations through buttresses or massive wall structures. The spacer can be reduced by decreasing the radius of the arc and increasing the cross-section of the arch, however, this option reduces the light transmission of the structure and is more material-intensive.

The spacer can also be extinguished by installing a horizontal tightening, which greatly facilitates the construction

and installation of supports, to which only vertical loads are transmitted in this case. Besides its own weight, the arch is subject to wind and snow loads, acting irregularly and unevenly. If the load is unevenly distributed, the arch begins to bulge and needs to be stabilized. In fact, diagonal ties work well with uneven load, protecting the unloaded half of the arch from bulging, working in tension and being one-sided switchable ties that work only in case of load.

STRUCTURAL ANALYSIS

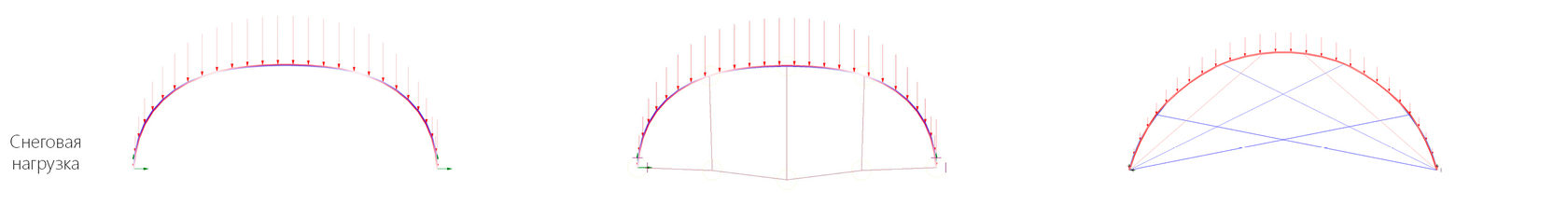

We performed structural analysis (Karamba3D) and compared the deformation of arches of the same cross-section (75 x 55 mm) and span: a) without ties, b) with horizontal tie and hangers, c) with diagonal ties.

1) Arch without a tie with rigid (not moving) supports

The tension is transferred directly to the supports. Deformation from snow load - 9 cm, from wind load - 21 cm. The arch deforms in a characteristic way, sagging in the middle part and bulging on 1/4 of the span.

2) Arch with one horizontal tie and three hangers, with one fixed and one free support.

The thrust is compensated by the horizontal tie but does not affect the deflection of the arch under the snow load.

We performed structural analysis (Karamba3D) and compared the deformation of arches of the same cross-section (75 x 55 mm) and span: a) without ties, b) with horizontal tie and hangers, c) with diagonal ties.

1) Arch without a tie with rigid (not moving) supports

The tension is transferred directly to the supports. Deformation from snow load - 9 cm, from wind load - 21 cm. The arch deforms in a characteristic way, sagging in the middle part and bulging on 1/4 of the span.

2) Arch with one horizontal tie and three hangers, with one fixed and one free support.

The thrust is compensated by the horizontal tie but does not affect the deflection of the arch under the snow load.

Vertical hangers exclusively support horizontal tie from sagging under its own weight. Deformation from snow load - 10 cm, from wind load - 21 cm.

3) An arch with three pairs of diagonal ties with one fixed and one free support.

Deformation from snow load - 0.75 cm, from wind load 0.57 cm. The comparison shows that deformations in an arch without ties and an arch with a horizontal tie are 37 times higher for the wind loads, 13 times higher from the snow loads than of an arch with diagonal ties. Analysis shows that the installation of diagonal ties of only 1 cm in diameter increases the rigidity of the structure by more than an order of magnitude.

MODEL

A scale of 1:25 was chosen for the physical model. All supporting elements of the structure were made of brass, the support structure - from wood and plywood base, the ties - from thin metal wire. In the first stage of preparation for the production, a 3D model was created, which included all the parts for production to scale. Further, drawings were prepared for production and material was purchased. In order to cut arches on a laser machine, drawings of arches with grooves for corners and holes for tie attachment were created.

For the purlins, we used ready-made brass angle profiles of 2 x 2 mm. For smaller parts such as secondary beams, 2 mm wire was used.

For the ties, a fishing line with a diameter of less than 1 mm was used.

A scale of 1:25 was chosen for the physical model. All supporting elements of the structure were made of brass, the support structure - from wood and plywood base, the ties - from thin metal wire. In the first stage of preparation for the production, a 3D model was created, which included all the parts for production to scale. Further, drawings were prepared for production and material was purchased. In order to cut arches on a laser machine, drawings of arches with grooves for corners and holes for tie attachment were created.

For the purlins, we used ready-made brass angle profiles of 2 x 2 mm. For smaller parts such as secondary beams, 2 mm wire was used.

For the ties, a fishing line with a diameter of less than 1 mm was used.

When all the details were cut out on the machine, and the material was prepared, the assembly of the model began. First, the individual arches were assembled together with the ties along the pattern to give the line the correct length. Then the base for the model was prepared, for which cornices were milled from wooden bars. After fixing the base for the model, the pre-assembled 24 arches with strings were attached to it with the required distance and fixed with glue.

The last stage was the installation of brass corners in the grooves of the arches, as well as the semi-arches of the glazing.

Photos of the model: Yurii Palmin

Gratitude

We express special gratitude to the A.V. Shchusev State Museum of Architecture and the curator of the exhibition “Shukhov. Formula of Architecture" to Mark Akopian for conducting an excurions tour of the exhibition and providing archival materials and calculations of V.G. Shukhov, chief architect of GUM Vladimir Kamyshnikov, teacher of MGSU Yuri Yuzhakov, chief engineer of Metal Yapi Vasily Anopchenko and associate professor of the Russian State Humanitarian University Ilya Pechenkin for constructive criticism of the projects.

Gratitude

We express special gratitude to the A.V. Shchusev State Museum of Architecture and the curator of the exhibition “Shukhov. Formula of Architecture" to Mark Akopian for conducting an excurions tour of the exhibition and providing archival materials and calculations of V.G. Shukhov, chief architect of GUM Vladimir Kamyshnikov, teacher of MGSU Yuri Yuzhakov, chief engineer of Metal Yapi Vasily Anopchenko and associate professor of the Russian State Humanitarian University Ilya Pechenkin for constructive criticism of the projects.

Sources

[1] Herbst V.I. Report at the meeting of the St. Petersburg Society of Architects on October 25, 1894 // Builder's Week. 1894. No. 44

St. Petersburg Metal Plant. A brief outline of the activities from 1882 to 1896, St. Petersburg, 1896.

Privilege # 266 for a new fastening system for metal arches. August 9, 1897. A set of privileges issued in Russia in 1897

Further reading

Razmadze, A.S. Upper shopping rows on Red Square: a historical outline. Kiev, 1894.

[1] Herbst V.I. Report at the meeting of the St. Petersburg Society of Architects on October 25, 1894 // Builder's Week. 1894. No. 44

St. Petersburg Metal Plant. A brief outline of the activities from 1882 to 1896, St. Petersburg, 1896.

Privilege # 266 for a new fastening system for metal arches. August 9, 1897. A set of privileges issued in Russia in 1897

Further reading

Razmadze, A.S. Upper shopping rows on Red Square: a historical outline. Kiev, 1894.